Turbine cabins

Turbine cabins

Panel cross section

Turbine cabins

Features

Turbine cabins, air filtrate sealing system and filter houses are made for containing filtered air, to protect the turbine mechanic integrity and to avoid gas leaks to the media.

The turbine cabines consist of panels built in different layers to seal and isolate noise and heat and seal the filtered air. The assembly between doors and panels are by means of special shaped gaskets sealed air tight. Further parts are included as custom made ducts, textile expansion joints, locks, dampers, actuators, sealing monitor devices.

The turbine cabines consist of panels built in different layers to seal and isolate noise and heat and seal the filtered air. The assembly between doors and panels are by means of special shaped gaskets sealed air tight. Further parts are included as custom made ducts, textile expansion joints, locks, dampers, actuators, sealing monitor devices.

Advantages

Each panel is made of different material layers, stiffened by special diamond shape bends in the metal sheet, put together by nails and rivets, the different material layers isolate noise and heat. For the windows special template glass is used and sealed by elastomeric gaskets.

Recommended applications

Similar products

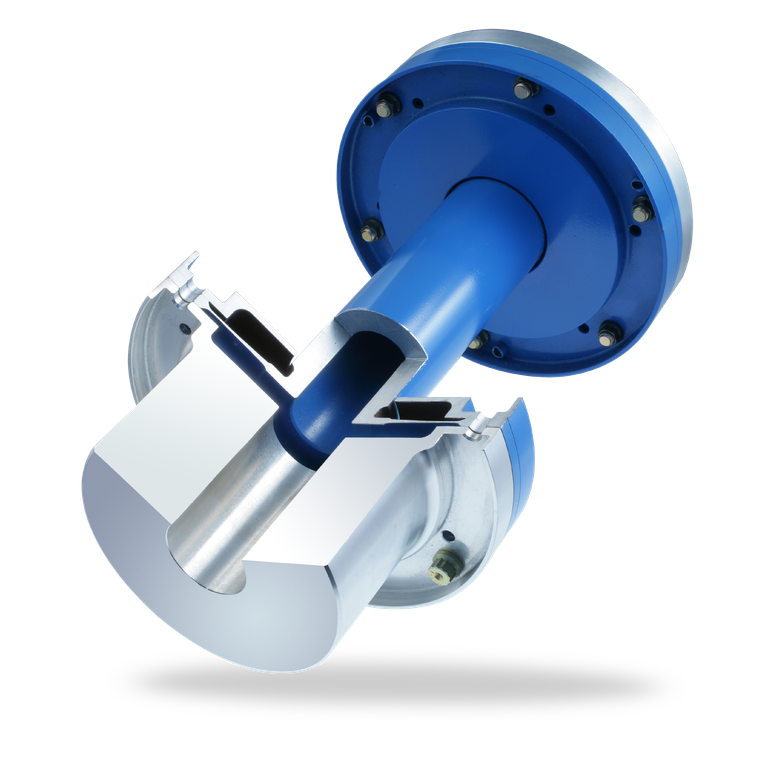

Diaphragm Coupling Model 99 API 671 / ISO 10441

- Torsionally rigid, flexible coupling for backlash-free torque transmission

- Very high torque and speed transmission

- Compensation in axial, radial and angular shaft misalignment possible

- Hyperbolic curved diaphragm with constant torsional shear stress

- High temperature-resistance

- Maintenance-free

- Highest precision and reproducibility with modern production technology using electron beam welding

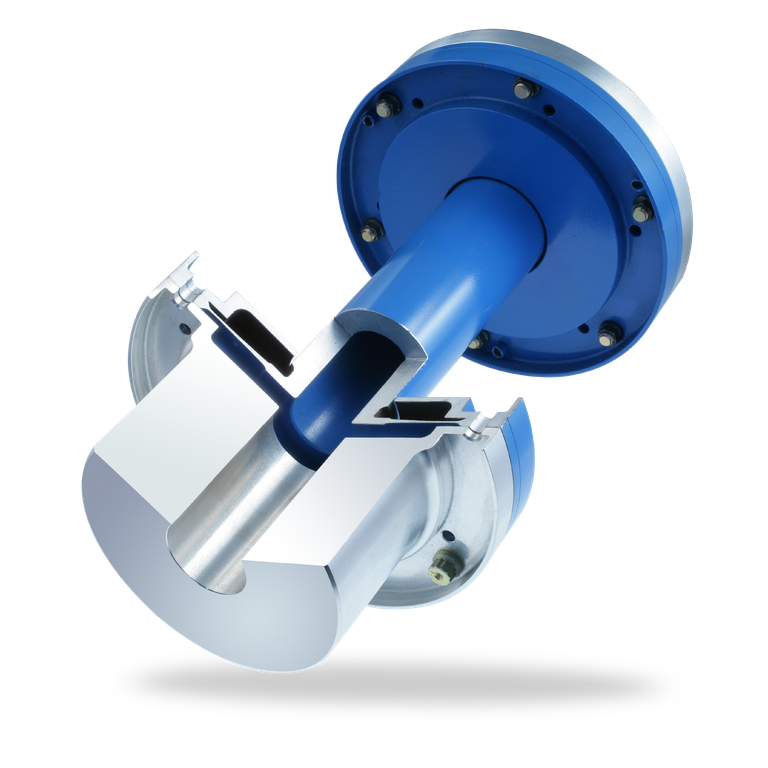

Diaphragm Coupling Model 100 API 671 / ISO 10441

- Torsionally rigid, flexible coupling for backlash-free torque transmission

- Very high torque and speed transmission

- Compensation in axial, radial and angular shaft misalignment possible

- Hyperbolic curved diaphragm with constant torsional shear stress

- High temperature-resistance

- Maintenance-free

- Highest precision and reproducibility with modern production technology using electron beam welding

DRO Rotary kiln sealing system

- Packing rings (self-adjusting) with permanent spring-action for optimal, continuous contact with the seal disc, optical wear indicator

- Can be pressurized with buffer gas

- Optional dust extraction at the expansion joint

- Optional flush fitting to remove dust deposits at the seal disc

- Double-acting seal rings for use with process-compatible barrier gas or to drain toxic or aggressive gas

- Cutting-edge materials, supports broad range of applications