APItex-S

APItex-S

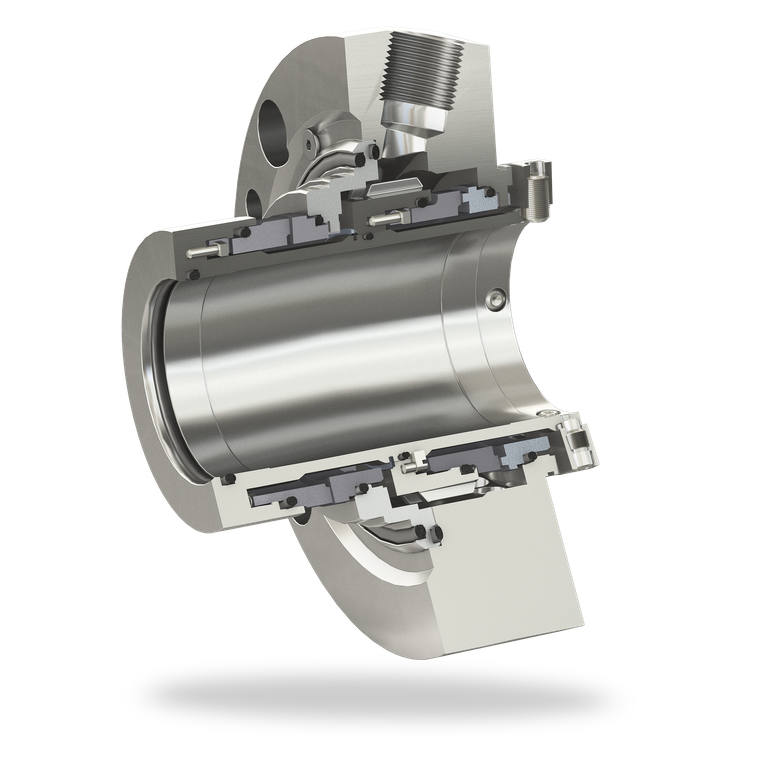

| Item | Description |

| 1 | Seal face |

| 2, 5, 7, 10 | O-Ring |

| 3 | Spring |

| 4 | Seat |

| 6 | Shaft sleeve |

| 8 | Cover |

| 9 | Inset |

| 11 | Set ring |

| 12, 15 | Set screw |

| 13 | Assembly fixture |

| 14 | Socket head screw |

| 16 | Screw plug |

F Flush

Q Quench

D Drain

APItex-S

Features

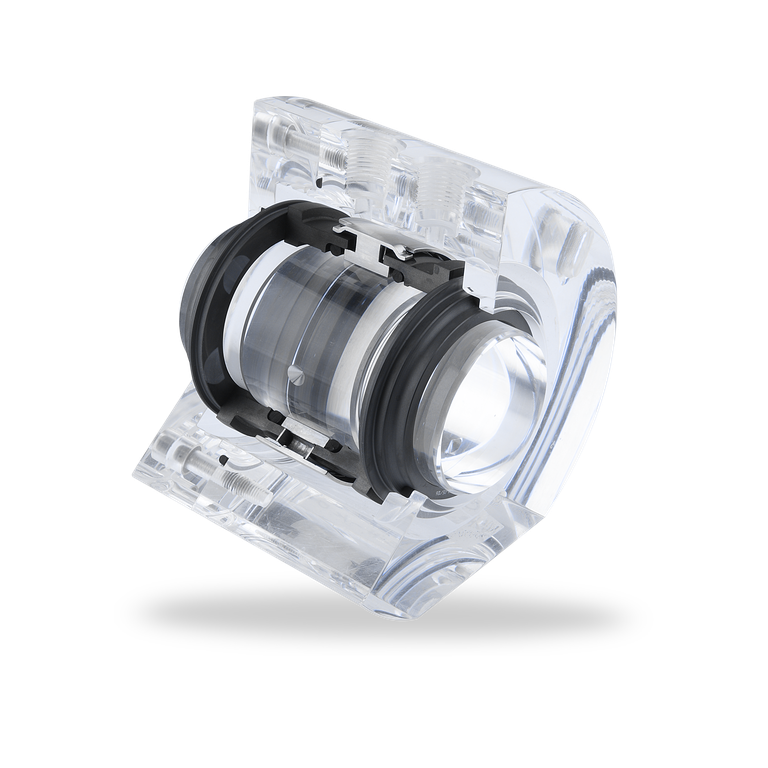

- API 682 Category 1, Type A, Arrangement 1 seal

- Single seal

- Balanced

- Cartridge unit

- Independent of direction of rotation

- Solid seal face

- Solid seat

Advantages

- 100 % API compliant

- Security due to proofed design (API Seal qualification test)

- Insensitive to shaft deflections and process fluctuations

- Pre-assembled, ready to install unit

- Low space requirements

- Springs protected from the product

- Multipoint Ring Injection for optimized cooling distribution

- Quench connections as standard

Materials

Seal ring: Silicon carbide SSiC (Q1)

Mating ring: Silicon carbide SSiC (Q1), antimony impregnated carbon graphite (B)

Secondary seals:

EPDM (E), FKM (V), FFKM (K)

Springs: Hastelloy C-4 (M)

Metal parts: CrNiMo steel 316 (G) or equivalent,

optional materials on request.

Mating ring: Silicon carbide SSiC (Q1), antimony impregnated carbon graphite (B)

Secondary seals:

EPDM (E), FKM (V), FFKM (K)

Springs: Hastelloy C-4 (M)

Metal parts: CrNiMo steel 316 (G) or equivalent,

optional materials on request.

Standards and approvals

- API 682 3rd ed. Cat. 1 / ISO 21049

- API 682 4th ed. Cat. 1

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Highly volatile hydrocarbons

- Toxic and hazardous media

- Media with poor lubrication properties

- Low solids content and low abrasive media

- CCUS

- Lithium

- Hydrogen

- Sustainable plastics production

- Alternative fuels production

- Power generation

- Vertical and horizontal ANSI chemical standard pumps

Recommended piping plans

Process side:

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 13

API Plan 14*

API Plan 21

API Plan 22

API Plan 23*

API Plan 31

API Plan 32

API Plan 41

Atmospheric side:

API Plan 51

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

API Plan 66A*

API Plan 66B*

* Non standard

API Plan 01

API Plan 02

API Plan 03

API Plan 11

API Plan 12

API Plan 13

API Plan 14*

API Plan 21

API Plan 22

API Plan 23*

API Plan 31

API Plan 32

API Plan 41

Atmospheric side:

API Plan 51

API Plan 61

API Plan 62

API Plan 65A

API Plan 65B

API Plan 66A*

API Plan 66B*

* Non standard

Similar products

APItex-T

- API 682 Category 1, Type A, Arrangement 2 or 3 seal

- Dual seal in face-to-back arrangement

- Balanced

- Cartridge unit

- Independent of direction of rotation

- Solid seal faces

- Solid mating rings

CGSH-KD

- API 682 Category 2 and 3, Type A, Arrangement 3 seal

- Dual seal in back-to-back arrangement

- Cartridge unit

- Independent of direction of rotation

(with U-grooves) - Gas-lubricated

- Contact free operation, no friction

- Rotating multiple springs

H75A4-B

- API 682 Category 2 and 3, Type A, Arrangement 3 seal

- Dual seal in back-to-back arrangement

- Balanced

- Cartridge unit

- Rotating multiple springs

- Integrated pumping device

- Suitable for pressure reversals